We keep tight

Sealing elements from MST

We have been offering the following sealing elements specifically for vacuum technology applications for many years:

Our seals have been used in vacuum chambers and vacuum technology components for many years, primarily by well-known vacuum system manufacturers in Germany and abroad.

Our seals have been used in vacuum chambers and vacuum technology components for many years, primarily by well-known vacuum system manufacturers in Germany and abroad.

In addition to our technical expertise and delivery reliability, our existing customers have appreciated our flexibility for many years.

In special cases, we are able to manufacture and dispatch the required gaskets within a few hours (without surcharges).

The raw materials are sourced exclusively from reputable European suppliers.

Optionally, it is possible to provide us with the round cord material free of charge (cost reduction).

–

PRODUCT EXAMPLES:

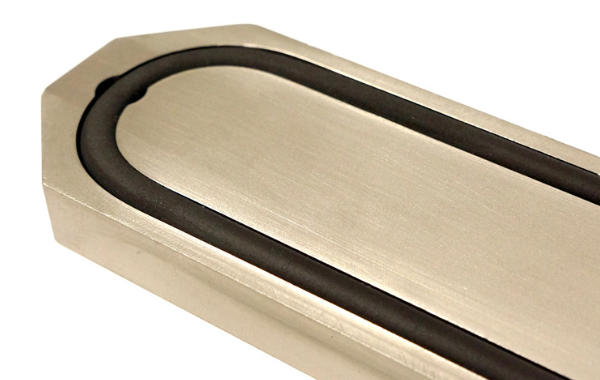

Application example:

Sluice gate

Shock-vulcanized seals

in various geometries

Butt vulcanization enables the production of a joint that meets the requirements of high-vacuum technology. This is essential for sealing points between vacuum chambers that are no longer accessible after installation.

In the production of our yard goods, there is no burr in the longitudinal direction, as is usually the case with injection-molded gaskets.

The raw material complies with the generally applicable DIN ISO 3302-1 class E1 standard.

Production of round cord seals according to individual customer specifications in terms of profile thickness, diameter and material.

Production of various round cord thicknesses from 1mm – 12mm in combination with any diameter.

Production of special geometries, such as lip seals, in standard dimensions and materials: e.g. 10 x 15 NBR.

Materials such as FPM/FKM and NBR can be manufactured in various Shore hardnesses as standard. Other materials on request.

O – RINGS

Our product portfolio includes the manufacture of high-quality O-rings that are especially suitable for high-vacuum applications.

We offer a wide range of dimensional combinations paired with different materials for individual applications.

Our good network in the industry enables us to supply special O-rings at short notice.

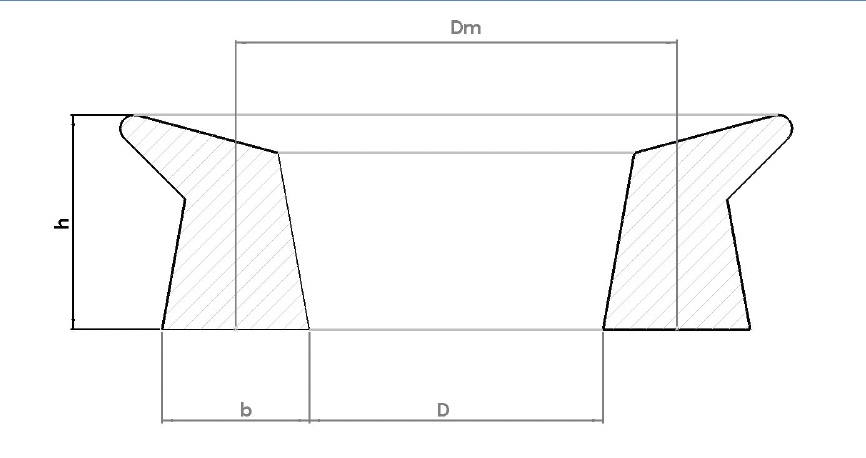

Order example lip seal:

Lip seal 10 x 15 x 1000 NBR

b= 10mm h = 15 mm

L = 1000 mm Material: NBR

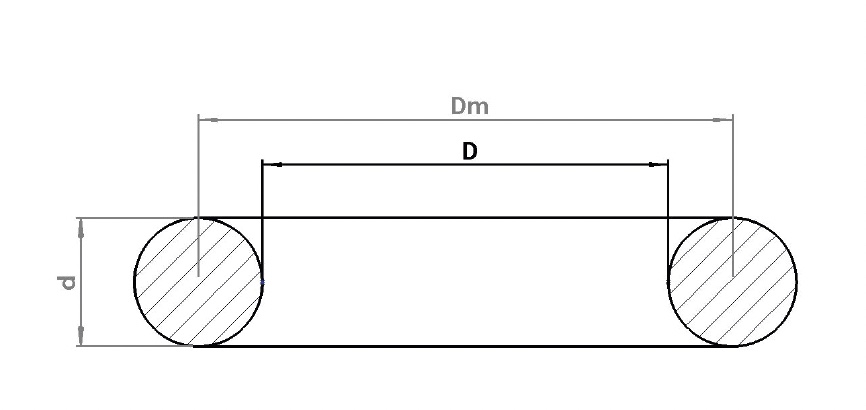

Ordering example R-ring:

R-ring 250 x 10 FPM

Round cord ring d= 10 mm D= 250 mm

Material: FPM

MST Technology GmbH & Co. KG

Quality made in Germany

The region in and around Hanau is historically influenced by vacuum technology, which is still clearly noticeable today. We combine our partners’ many years of experience in vacuum coating technology on a project-specific basis. The short distances but also the good connection to the Rhine-Main area in the middle of Europe are fundamental for good cooperation with customers and partners worldwide.