Project Examples

MST Technology GmbH & Co. KG is active in not only constructing new, but also upgrading and relocating existing vacuum coating lines for production, research and development.

Here are some examples of our projects. Contact us for competent support.

Development of a horizontal In-Line Coating System

New development of a horizontal In-Line coating system for 3D coating of substrates using PVD process. Automatic loading and unloading of substrates on a carrier. Inclusion into a linear linked production process in hardware and software.

Combining two vertical In-Line PVD systems

Combining two vertical In-Line PVD systems in PR China.

Dismantling of existing system.

Reconstruction and combining the two systems.

Conversion and extension of process functions:

- Pulsed DC coating compartments

- In-Line coating thickness measuring system

- Upgrade from planar cathodes to rotatable cathodes

- Extension of subsystems: vacuum technology, coolant, safety features and equipment, process gas supply, power supply (P.R.China)

Extension of functions of a 7° In-Line PVD system

- Extension of functions of a 7° In-Line PVD system with output increase of 100%

- Extension of chamber- and vacuum system

- Extension of process function: Conversion of rotatable cathodes and HF planar cathodes and heating

- Integration in the factory by means of Yaskawa robot system

- Extension of subsytems: coolant, safety features and equipment, process gas supply, power supply (P.R.China)

Relocation and extension of functions of a 7° PVD In-Line system

- Relocation of 7°PVD In-Line system from Germany to P.R.China with extension of functions

- Integration in the factory by connection of ABB robot system

- Changeover between existing DC and new MF equipment including implementation of an operating mode for reactive processes. Retrofitting of heating systems. Expansion of sub-systems: coolant, safety features and equipment, process gas supply, etc. (P.R.China)

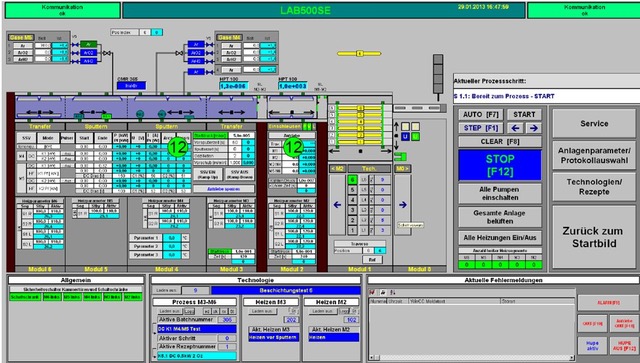

Development and construction of laboratory equipment for F&E

Development and construction of a lab-system for F&E in co-operation with a notable research establishment in Baden-Württemberg.

Load Lock 7° In-Line system.

Redevelopment and construction of a pilot production line

Redevelopment and construction of a pilot production line in an industrial co-operation for the OLED Lighting market for the end customer in Nanjing P.R.China.

7° In-Line PVD system with carrier return track.

New construction of vertical PVD In-Line systems

New construction of vertical In-Line systems for the deposition of ITO and SIO2 (P.R.China)

Retrofit of vertical In-Line coating lines

MST Technology GmbH & Co. KG

Qualität made in Germany

The region in and around Hanau is historically characterized by vacuum technology, which is still clearly noticeable today. We bring together our partners’ many years of experience in vacuum coating technology on a project basis. The short distances but also the good connection to the Rhine-Main area in the middle of Europe are fundamental for the good cooperation with customers and partners worldwide.

References and application

Qualität made in Germany

Our customers, who are at home in a wide range of industries, rely on our expertise:

- Display

- Automotiv

- Solar